What Are You Looking For?

What Are You Looking For?

♦Pulse mode: monopulse/double-pulse/orthogonal pulse

♦Signal level: 3.3~24V compatible; series resistance not necessary for the application of PLC

♦Power voltage: 24-50V DC supply; 36 or 48V recommended

Item No :

SC60Order(MOQ) :

5Payment :

T/TProduct Origin :

ChinaSC60 two-phase stepper driver

The SC60 Digital 2-phase Stepper drive is based on TI's 32-bit DSP platform and integrated with the micro-stepping technology and the auto tuning of power-up parameters. With the features of low noise, low vibration, low heating and high-speed high torque output, it is suitable for most stepper motors.

Typical application: carving machine, marking machine, cutting machine, plotter, laser, auto assembly equipment

Product Specification

| Pulse mode | Single/double pulse | |||

| Signal level | 3.3~24V compatible,no series resistance required for PLC applications | |||

| Power supply voltage | 24-50V DC power supply,36 or 48V recommended | |||

| Typical Application | Engraving machine,marking machine,cutting machine,plotter,laser,automatic assembly equipment,etc | |||

| Operating voltage range | 18VDC~48VDC | |||

| Operating current range | 1.4~5.6 A | |||

| Matching motor | Motors up to 42 series,57 series,and 86A4 | |||

| Rich control signal interface | PUL&DIR,CW+CCW,can be differential,common negative,common positive connection | |||

| Control signal interface level | 3.3V~24VDC,no external current limiting resistance required | |||

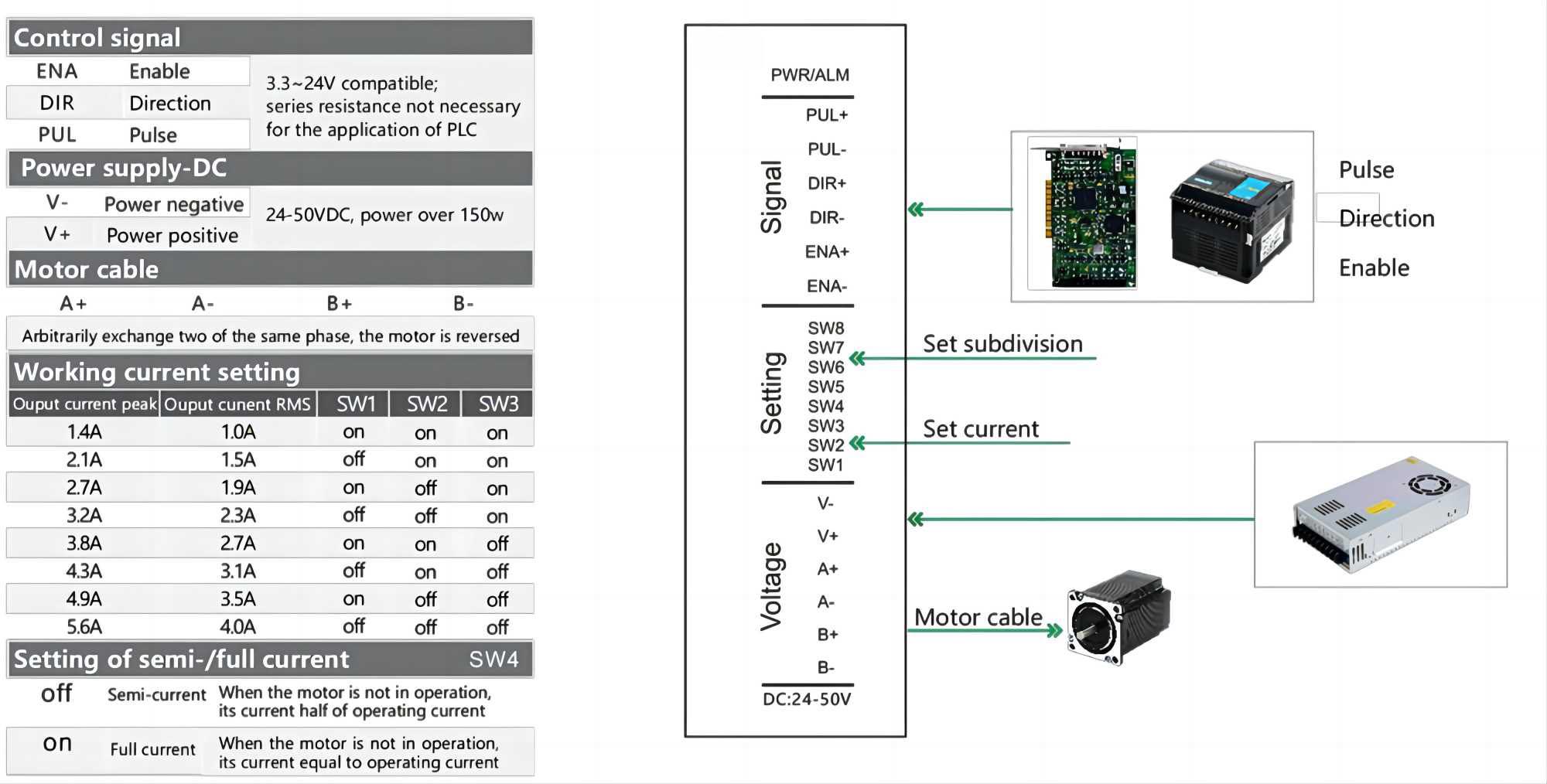

Driver function

| Driver function | Operating instructions |

| Microstep fine score setting | SW5-SW8 Four dip switches are used to select a total of 16 micro step subdivisions.Please select the corresponding subdivision by referring to the driver panel,and ensure that the drive is not active when setting. |

| Output current setting | SW1-SW3 Three dip switches are used to select a total of 8 output currents.Please select the corresponding current against the driver panel,and ensure that the driver does not operate when setting. |

| Automatic half-current function | SW4 is used to set the automatic half-stream function of the drive.off means that the static current is set to half of the operating current,and on means that the static current is the same as the operating current.In general use, SW4 should be set as off,so that the heat of the motor and the driver is reduced and the reliability is improved. About 0.4 seconds after the pulse train stops,the current will be automatically halved |

| Signal interface | PUL+and PUL-for the positive and negative ends of the control pulse signal;DIR+and DIR-for the positive and negative end of the direction signal;ENA+and ENA-for the positive and negative ends of the enable signal. |

| Motor interface | A+and A-are connected to the positive and negative ends of the A-phase winding of the stepper motor;B+and B-are connectedto the positive and negative ends of the B phase windings of the stepper motor.When the A and B phase windings are switched,the direction of the motor can be reversed. |

| Power interface | Use DC power supply,SC60 operating voltage range is recommended to be 24-50VDC,power supply power greater than 150W. |

| ndicators | The drive has two indicator lights,red and green.The green light is the power indicator,and the green light blinks when the driver is powered on;The red light is the fault indicator,when there is overvoltage, overcurrent fault,the fault light blinks.After the fault is cleared,the red light turns off.When the drive fails,the fault can only be cleared by re-powering and re-enabling it. |

SC60 Connections

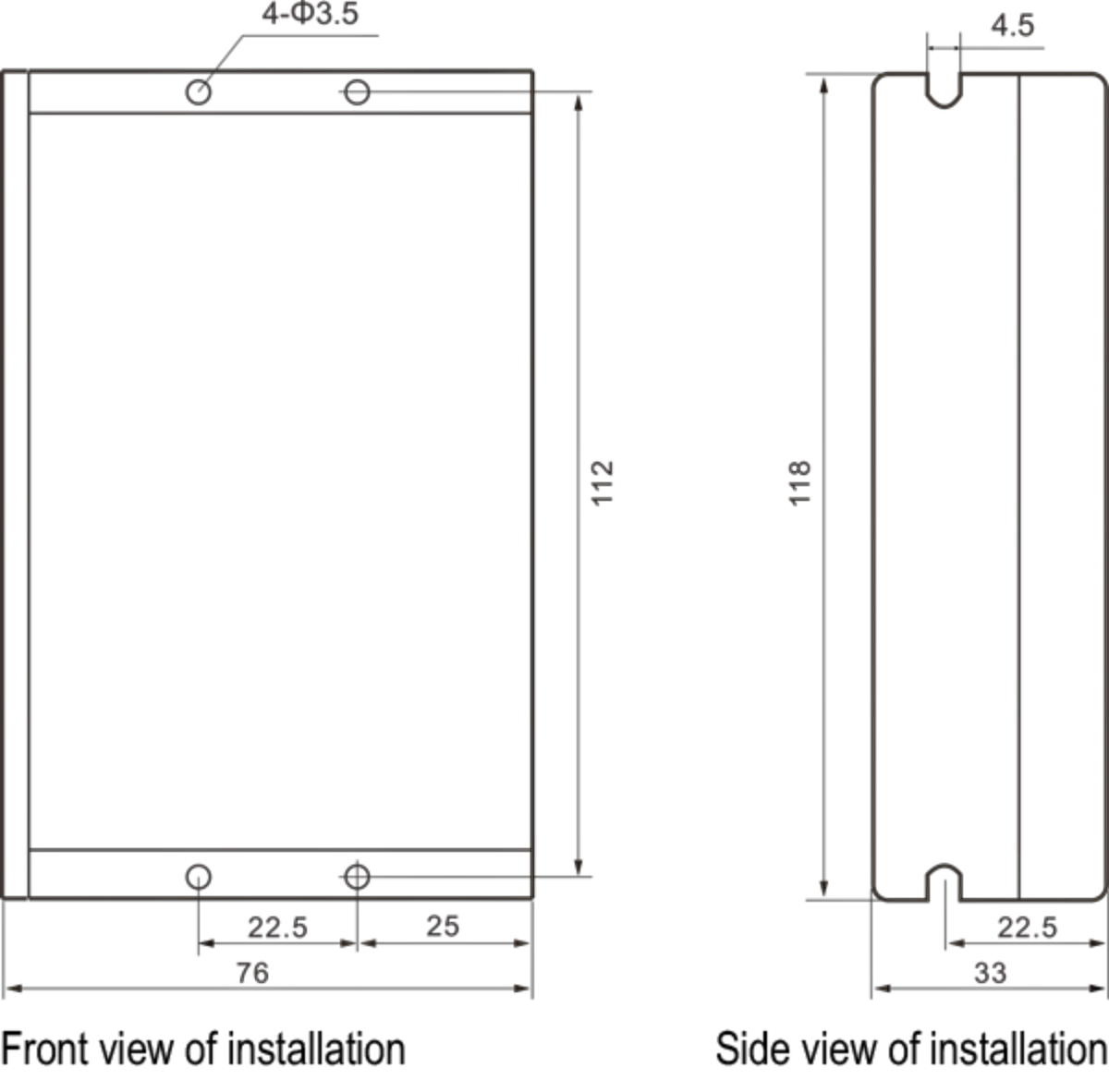

Product Dimensions

FAQ

Can we accept samples customized?

No problem for samples order, and welcome your testing before your big order.

OEM and ODM are available?

Yes, we accept customized products

Can I get a lower price if I order large quantities?

Yes, Cheaper prices with bigger size orders, please contact us and we will give you a quatation.